Advantech and Sunforce Collaborate on a Smart Monitoring System for Taiwan’s First Micro-biomass Power Plant

07/04/2021

Advantech and Sunforce Collaborate on a Smart Monitoring System for Taiwan’s First Micro-biomass Power Plant

Project summary

System requirements

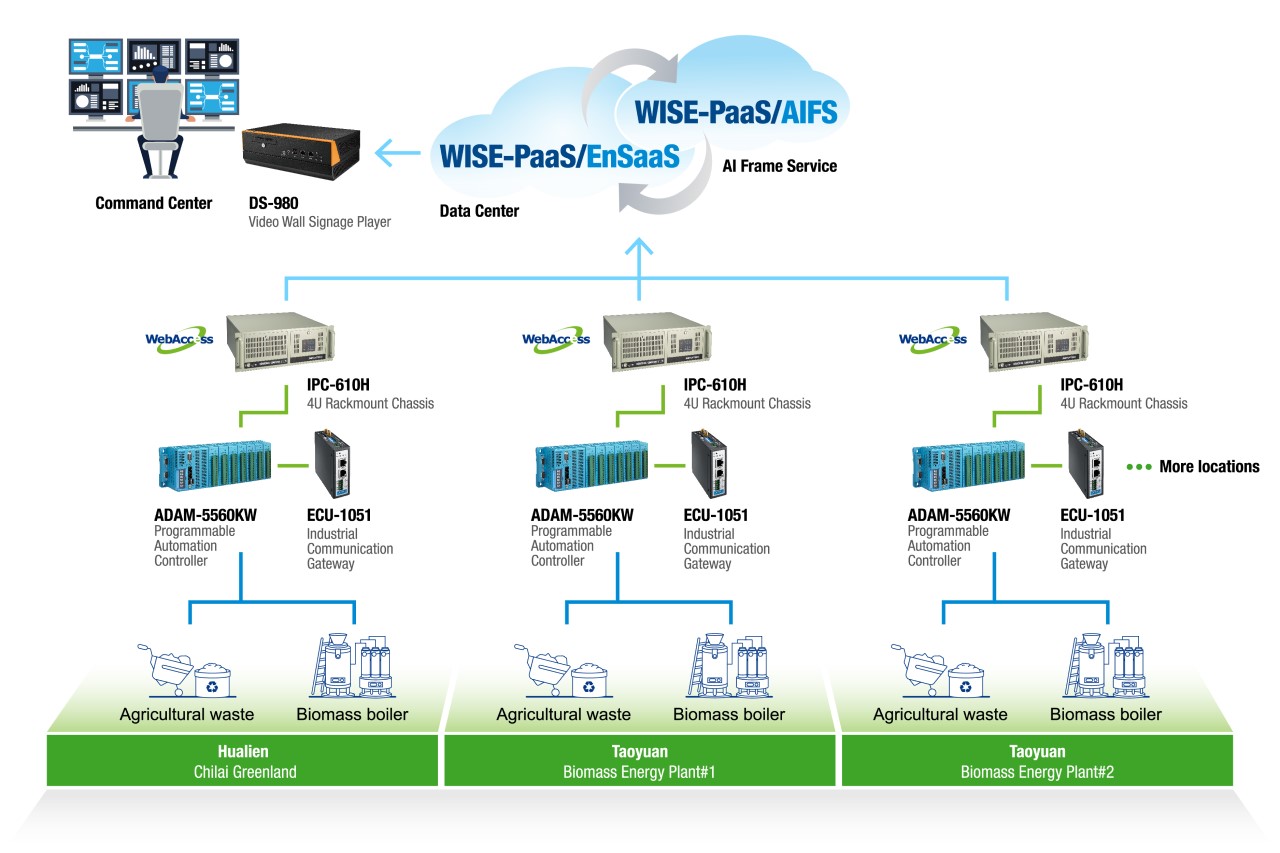

Sunforce, a SCADA system integrator specializing in remote intelligent control solutions, has over ten years of experience in industrial automation control, intelligent agricultural applications, and green energy/environmental safety monitoring systems. Sunforce was asked to develop a monitoring system for micro biomass power plants due to their extensive system integration experience. Located in Hualien, these green-tech biomass facilities specialize in converting agricultural and residential waste into energy; and are the first of their type in Taiwan. A typical Taiwanese incinerator burns around a thousand tons of waste every day; conversely, this biomass power plant converts 50 tons of waste into energy every day.

As this solution was the first of its kind in Taiwan, its designers were eager to harness IoT and cloud computing solutions. They hoped these solutions would reduce labor expenses and equipment failure rates while increasing power generation. They also wanted to perform scheduling and cascade control to create standard operating procedures aimed at achieving remote monitoring and real-time management. In the future, they will combine artificial intelligence with gradually accumulated operational data to perform intelligent monitoring.

To meet these requirements, Sunforce chose a combination of hardware and software products aimed at enabling automation in the monitoring system’s first phase and intelligent monitoring in the second phase. Hardware stability, software inerrability, and solution scalability/reproducibility influenced Sunforce’s decision to choose these solutions.

System overview

Project implementation

- WebAccess/SCADA : Browser-Based SCADA Software

- IPC-610: 4U Rackmount Chassis with Visual Alarm Notification

- ADAM-5560KW: 7-slot Micro PAC with Intel® Atom™ CPU

System Architecture

-25/Project_02--_Vertical20220406173334.jpg)